Discover servicesHigh-quality medicine box printingWith a professional design that ensures data clarity, product protection, and adherence to health standards and printing accuracy for your brand.

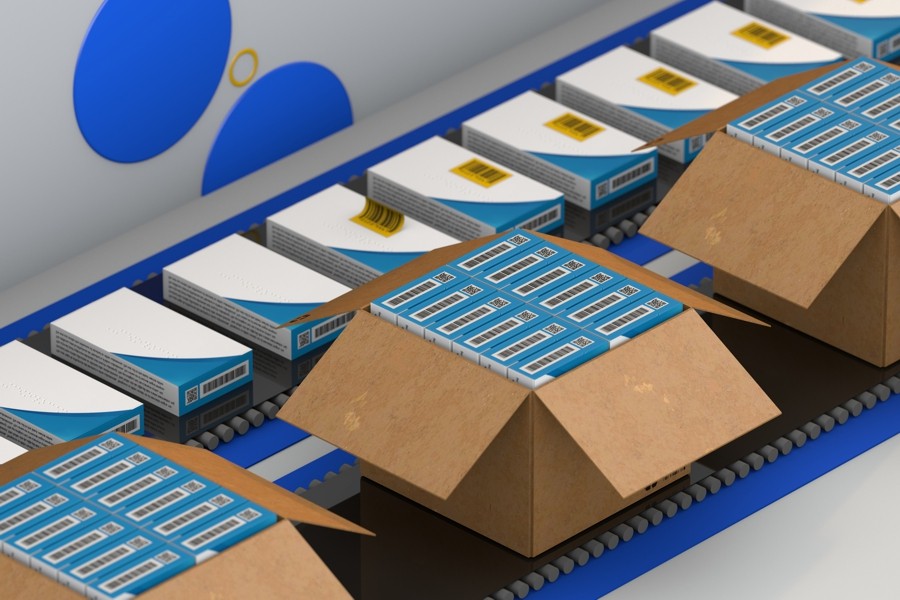

In the pharmaceutical industry, it is considered high-quality medicine box printing a necessity, not just an option. These boxes are not only a means of protecting the product, but also a tool for communicating with the consumer. When the printing is clear and precise, it's easier for the patient or pharmacist to read information about the dosage, drug ingredients, and expiration date. At Quality Printing and Packaging, we guarantee our customers superior printing quality using the latest printing technologies, giving the packages clarity and durability that reflect credibility and professionalism.

Requires high-quality medicine box printing. Strict adherence to international health standards, as any printing error could lead to confusion or misuse of the medication. We pay close attention to every detail, from the selection of approved medical paper or carton to the colors used in printing, which must be safe and non-toxic. We also ensure that security measures such as watermarks or secret codes are added to protect against counterfeiting and forgery.

When we talk about high-quality pharmaceutical packaging printing, we're referring to the integration of attractive design and practical functionality. Packaging must be durable to protect tablets or syrups from external factors such as moisture and light, while also featuring high-resolution prints that make instructions easy to read. At Quality Printing and Packaging, we use technologies such as offset and digital printing to ensure color accuracy and long-lasting stability.

If you are looking for companies high-quality medicine box printing. It's important to choose a company that combines experience, quality, and commitment to global standards. At Quality Printing and Packaging, we pride ourselves on being a strategic partner to the region's largest pharmaceutical companies, providing integrated printing solutions from design to final delivery. Our distinction stems from our reliance on the latest production lines and a trained team capable of handling the finest details.

Designing medicine boxes is a crucial step in the packaging production process. Good design is not just about aesthetics, but also about functionality, such as clear writing and organizing information in an organized, easy-to-read format. At Quality, we provide our clients with professional design services that take into account the pharmaceutical company's identity and adherence to medical standards, ensuring the delivery of safe and professional medicine packaging.

With the plethora of printing presses on the market, Quality Printing and Packaging stands out as one of the best pharmaceutical box printers due to its commitment to quality standards and the expertise of its technical team. We are distinguished by our use of high-quality materials, advanced printing techniques, and strict quality control at every stage. This makes us the preferred choice for pharmaceutical companies looking for a reliable printing press that delivers speed, accuracy, and adherence to deadlines.

Offset printing for medicine boxes is one of the most popular and effective methods in this field, due to its ability to produce accurate colors and clear details at high quality, even when printing in large quantities. At Quality, we provide offset printing services using modern machines that guarantee extreme precision and long-lasting color stability, giving medicine boxes a professional appearance that increases customer confidence in the product.

At Quality Printing and Packaging, we fully understand the importance of pharmaceutical packaging as an essential part of the marketing process and maintaining product safety. That's why we prioritize quality and commitment, providing you with pharmaceutical packaging printed to the highest standards of professionalism.

When talking aboutHigh-quality medicine box printingQuality is not just an option, but a necessity imposed by health laws and consumer expectations. The most important quality standards that must be adhered to are:

Clear printing so all medical information and instructions are easy to read, even in small sizes.

Use safe inks. The inks must be certified and free of harmful substances so as not to affect the safety of the medicine or contaminate the package.

Accuracy of colors and design, because any error in colors may cause confusion between different drug packages.

Resists transportation and storage factors such as humidity, heat, and scratches to ensure the box remains in its original condition until it reaches the consumer.

Compliance with international specifications such as GMP and ISO standards for the pharmaceutical and packaging sector.

Yes, clearly printing data and barcodes is an essential element in the pharmaceutical packaging industry, as advanced printing technologies such as offset printing or high-resolution digital printing are used to ensure clarity:

Drug name and brand name.

Pharmaceutical composition and dosage.

Production date and expiration date.

Barcode and QR code to track the product and ensure its authenticity.

The clarity of this data not only serves the patient but also helps pharmacies, hospitals, and distribution companies manage inventory efficiently.

Choosing the packaging material is an essential step to ensure that the quality of the medicine is maintained during storage and transportation. The choice is based on several factors:

What type of medication is it? Tablets, capsules, syrup, or injections. Each type has its own appropriate packaging material.

Shelf life: Some medicines require moisture- or light-resistant packaging.

Transportation and distribution requirements: If the medicine is to be exported to different countries, a material that can withstand long distances and climate changes must be chosen.

Marketing aspect: The material must reflect the brand's value and give a professional, eye-catching appearance.

The most popular materials used are treated medical cardboard, high-quality cardboard, and pharmaceutical-safe plastic.

Yes, it is possible. We offer integrated solutions for designing custom medicine boxes that reflect the brand identity. We provide:

Creative design that complies with health regulations.

Print company logo and brand colors.

Possibility of adding security technologies such as reflective layers or special seals to prevent counterfeiting.

Different designs to suit local or export medicines.

Custom packaging is not just packaging; it's a marketing tool that builds patient confidence and increases brand awareness.

Medicine box sizes vary depending on the type of medicine and the size of the inner package. The most common sizes are:

Small boxes for tablets and capsules (e.g. 3x7 cm or 4x10 cm).

Medium tins for syrup or creams (e.g., 6x12cm or 8x15cm).

Large boxes for multi-use medical products or family packs.

Fully customized sizes can also be manufactured based on customer needs and product type while maintaining compliance with storage and transportation standards.

When choosing a company to print medicine boxes, it's important to ensure they adhere to international quality standards and offer flexible solutions in design, sizes, and materials. At our company, we prioritize consumer safety and brand professionalism, providing printing and packaging services that meet the most stringent requirements with the highest levels of accuracy and reliability.

Time is a key factor in the pharmaceutical industry. Pharmaceutical companies need to deliver packaging as quickly as possible while maintaining the highest possible quality. At Quality Printing and Packaging, we place great importance on meeting deadlines. Therefore, we work according to a precise production plan that ensures the printing and delivery of medicine boxes on time.

The process takesHigh-quality medicine box. The turnaround time ranges from several days to a few weeks, depending on the size of the order, the complexity of the design, and the type of materials used. We also offer our customers a fast delivery service for urgent cases, while maintaining the same high quality standards.

Yes, we understand that some pharmaceutical companies or distributors may require limited quantities, whether to test a new product or launch a trial batch. At Quality Printing and Packaging, we offer complete flexibility in quantity selection, allowing you to order small or medium-sized prints at competitive prices and high quality.

This service helps startups or small businesses reduce initial costs while ensuring elegantly and professionally printed pharmaceutical packaging.

Choosing printing materials plays a crucial role in maintaining the safety of medicines. At Quality Printing and Packaging, we use high-quality materials such as moisture-resistant pharmaceutical cartons, paper designed for medical printing, and thermoplastics.

All of our materials are safe, hygienic, and compliant with international pharmaceutical packaging standards, protecting the product from contamination or damage and preserving its active ingredients until it reaches the patient.

Yes, one of the most significant challenges of storing medicines is their exposure to weather factors and various transportation conditions. At Quality Printing and Packaging, we use modern technologies such as high-resolution offset printing and printing with special protective layers that make printed text and data, such as barcodes, production dates, and expiration dates, resistant to moisture and heat. This ensures that the information remains clear and legible throughout the product's shelf life and maintains trust between the manufacturer and the consumer.

Packaging is not just the external appearance of the medicine, but it is the first line of defense to protect the product. Through good packaging:

Prevent moisture and air from reaching the product, which may spoil the formulation.

Protect packages during transportation and storage from breakage or leakage.

Maintain necessary information such as dosage, medical warnings, and production and expiration dates.

Enhance consumer confidence in the brand through a professional appearance and high quality.

At Quality Printing and Packaging, we keep these considerations in mind in every production process, and we are committed to providing packaging solutions that preserve the effectiveness of medicines and support the reputation of manufacturers.

Choosing a specialized company like Quality Printing and Packaging means you get high-quality, environmentally resistant printed medicine boxes in quantities that suit your needs, whether small or large, while remaining on schedule and ensuring complete protection of your medicine's safety.